Choosing The Right Faux Beam Style

At AZ Faux, we offer an impressive selection of styles from rustic to contemporary. All of our beams are custom made to your exact specifications. Available factory finished or unfinished, you’re sure to find the exact beam for your indoor or outdoor space. Use this guide to help decide which faux wood beam style is best for your project.

Rustic Beams

Rustic beams are just that, the perfect complement to an Italian or Old-World look or as an accent to 18th Century American décor. Our rustic or distressed beams feature deep cracks and splits and in one case, axe marks as if chopped by hand. Beam styles include Hewn, Magnolia, and Old Tuscan, and are available in a variety sizes, colors and prices.

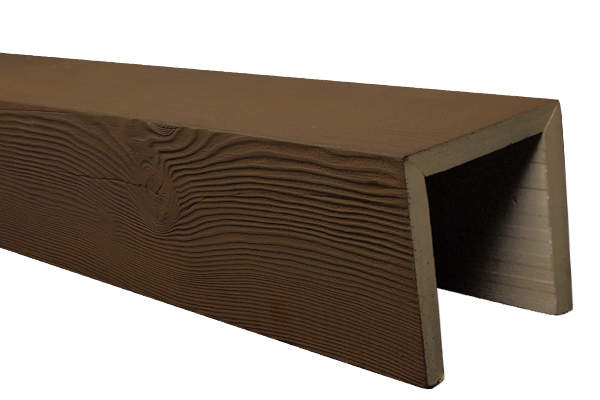

Raised Grain Beams

Our raised grain beams include Woodcrafted, Wind Drift, and Old Barn. Several of these are available as four-sided beams for applications such as truss systems or in any other setting where the top of the beam would be visible from above.

Pebbled Beams

Look no further than our mill cut beams for that rough-sawn cedar texture. Our Saw Cut style feature a “pebbled” texture as if cut on an old circular blade in a lumber mill. Like our raised grain and rustic beams, mill cut beams are available in a wide variety of sizes, lengths and colors.

Rustic Faux Wood Beams

Hewn

Magnolia

Old Tuscan

Raised Grain Faux Wood Beams

Wind Drift

Woodcrafted

Old Barn

Pebbled Faux Wood Beams

Saw Cut

A Quick Word About Pricing

There are many factors that go into what determines the selling prices of faux wood product, and for the average customer, it can be a bit confusing figuring out what is the best value when comparing our beams to those of our competitors.

In an "apples to apples" comparison (production method, size, finished or unfinished, etc. all being equal), the density of the polyurethane foam used from one beam to another is generally, but not exclusively, the difference. A higher density foam (greater weight per cubic foot) usually results in a higher price. Different factories use different foam densities, which partly explains the pricing differences you see when comparing our prices to those of other faux wood product sellers.

Higher density foam generally produces a slightly better representation of the wood grains and textures used in the molding process, but when it comes to making a final decision, you should certainly also consider style/texture, color options, size options, production lead time and quality of customer service in making your choice of product.